● Weighing Systems

● Simon MDS

● Bosch SMP

● Penko

● Machines and Plants

● Dosing Unit

● Raw Material Dosing

● Reference Projects

● Programming

● Coil Handling Station

● Production Line EAMB

● SCADA

● Test Unit for Valves

● Circuit Diagrams - Tests

● Switch Cabinet

● Dosing Unit

● S7-300 Danfoss FU

● Siemens C613

● contact

● Deutsche Seite

● Simon MDS

● Bosch SMP

● Penko

● Machines and Plants

● Dosing Unit

● Raw Material Dosing

● Reference Projects

● Programming

● Coil Handling Station

● Production Line EAMB

● SCADA

● Test Unit for Valves

● Circuit Diagrams - Tests

● Switch Cabinet

● Dosing Unit

● S7-300 Danfoss FU

● Siemens C613

● contact

● Deutsche Seite

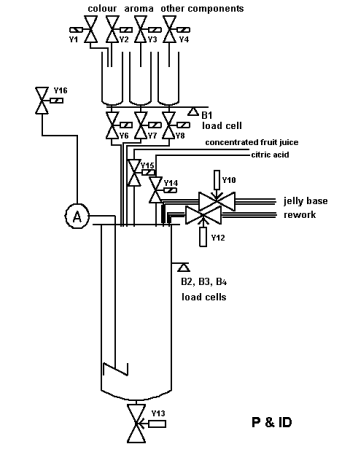

Dosing unit FACJ40ApplicationThe FACJ40 is a modular, compact and fexible unit for the gravinetric dosing and mixing of 4 to 40 litres of conventional gum and jelly confectionery as well as foamed confectionery featuring high adaptability to specitic process requirments. Unit configuration Heatable mixing vessel with 40 litres capacity. 1 to 4 1-litre dosing vessels. Independent weighing points for additves and the base component. The unit construction conforms to HACCP standards, thus doing away serveral CCP's. The product is fed via compressed air directly from the supplier's transport containers, simplifying both the process sequence and the cleaning. Unit advantages Simple replacement thanks to easy access to major unit components. Storage vessels for colour, aromas and fruit juice concentrate are no longer necessary. Dosing accuracy for small amounts, minimum 0.8 grammes. Dosing accuracy for base component, minimum 15 grammes. Seperate dosing vessels for small amounts with individual outlet. The components are only mixed as they enter the mixing vessels. Different stirrers are available depent on the process requirements. Narrow mixing vessels reduces residues. The recipe-controlled mixing of special colours is possible. Linking the dosing controller to an ACCESS databank enables the monitoring and analysis of the product to IFS and IPC. The controller can be connected to ERP. No risk of physical product contamination. Technical Data: Dimension: HxBxT 1900x500x500 mm Materials: stainless steel 1.4301(SS304), alterantively 1.4571(SS316Ti) Hoses Kynar-PVDF, alterantively PTFE Weight: 140 kg Voltage: 230 VAC, 50 Hz Compressed air: 6 bar Mixing vessel: Capacity: 40 l, headable with water, 3 bars Inlet pipe for base components DN40, heatable Inlet pipes for other components DN10 Outlet DN65 Compressed-air stirrer mounted on vessel lid. Speed adjustable with air flow. Consumption: 30 to 60 l/min at 6 bar. Additional components dosing vessels: 1 to 4 Units are possible, each with 1 litre capacity. Aternatively up to 2 units with 3 litres capacity each.  P&ID example scheme |

|